詳情(qing)介紹(shao)

| 品牌 | 其他(ta)品牌 | 加工(gong)定(ding)制 | 否 |

|---|

| 林格(ge)曼黑(hei)度(du) | 0級(ji) | 脫硫(liu)率(lv) | 99% |

|---|

| 除塵(chen)率(lv) | 99% | 阻力(li)損(sun)失(shi) | 100Pa |

|---|

| 出口含(han)塵(chen)濃(nong)度(du) | 10g/Nm³ | 使(shi)用溫度範(fan)圍 | 《80℃ |

|---|

| 液氣(qi)比(bi) | 5 | 處(chu)理風(feng)量(liang) | 950-8000m³/h |

|---|

| 過(guo)濾(lv)速(su)度 | 80m/min | | |

|---|

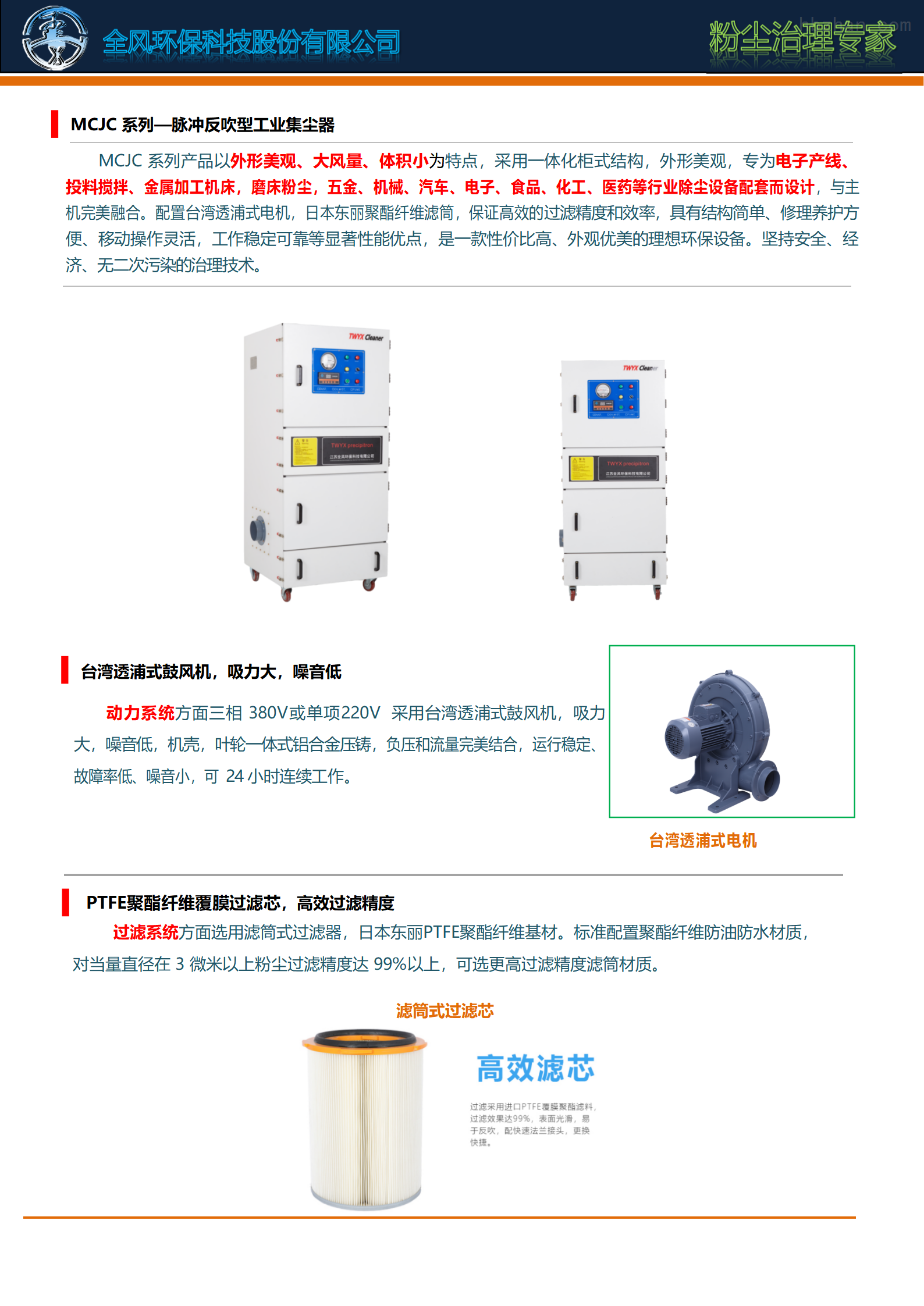

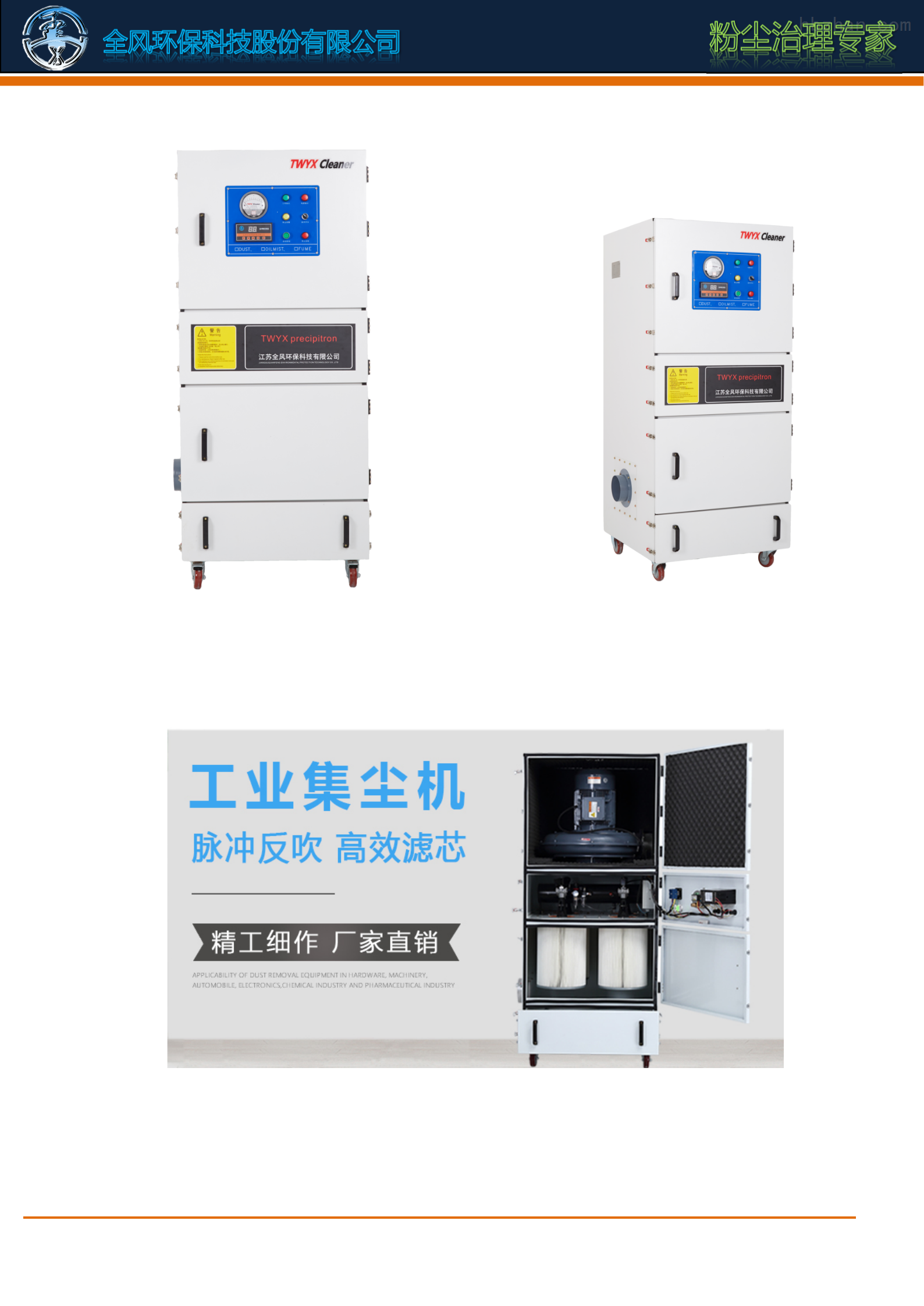

工(gong)業全(quan)自動(dong)吸(xi)塵(chen)器(qi)

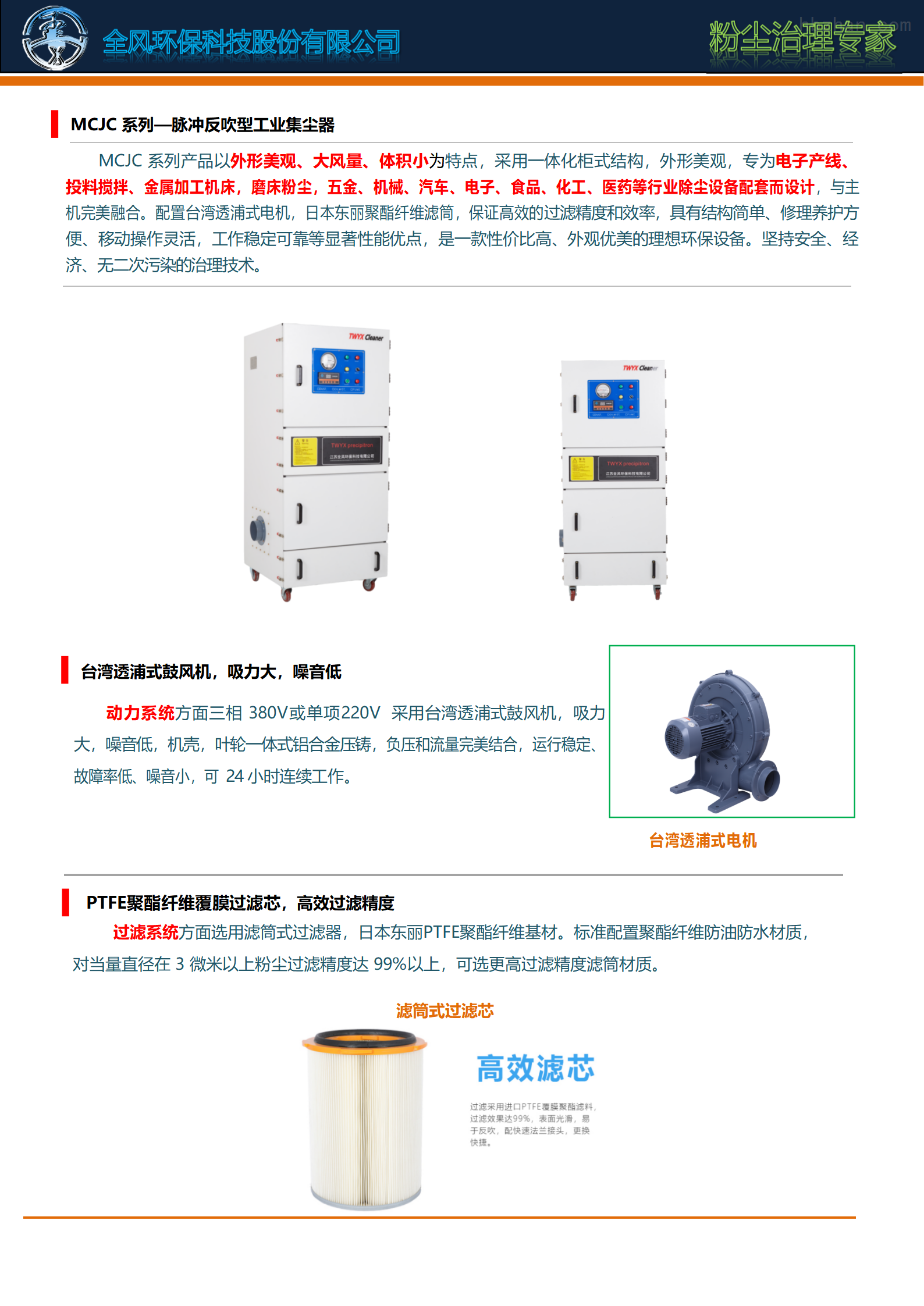

工(gong)業吸(xi)塵(chen)器(qi)與(yu)家(jia)用(yong)吸(xi)塵(chen)器(qi)原(yuan)理基本(ben)上是(shi)壹樣(yang)的,圓筒(tong)褶皺(zhou)式濾筒(tong)設計可(ke)使(shi)過(guo)濾(lv)面積(ji)高(gao)達(da)10-20平(ping)方(fang)米(mi),通(tong)過(guo)風(feng)機(ji)或(huo)者(zhe)氣(qi)泵使(shi)機(ji)器(qi)內部的空氣被抽(chou)出,這樣機(ji)器(qi)內外(wai)部(bu)產(chan)生了壓(ya)力(li)差(cha),也(ye)就(jiu)是(shi)所(suo)謂的負壓(ya),負壓(ya)越高(gao),吸(xi)力越強(qiang)。工(gong)業用(yong)吸塵(chen)器(qi)的種(zhong)類(lei)居多,使(shi)用方(fang)法因(yin)此(ci)也(ye)比(bi)較(jiao)多,可(ke)單(dan)獨(du)使(shi)用亦(yi)可(ke)配(pei)套(tao)使(shi)用,吸(xi)塵(chen)器(qi)其實是(shi)很簡單(dan)的機(ji)器(qi)設備,主要(yao)有(you)壹個漩(xuan)渦(wo)氣泵或風(feng)機(ji)進(jin)行抽(chou)風(feng),雜(za)物(wu)經(jing)吸(xi)嘴(zui)和吸(xi)塵(chen)管進(jin)去(qu)機(ji)器(qi)後,先(xian)進入(ru)壹個過(guo)濾(lv)布袋,壹般(ban)是(shi)無紡布的,經過(guo)初(chu)級(ji)過(guo)濾(lv),攜(xie)有(you)細小(xiao)的灰塵(chen)的空氣再(zai)經(jing)過(guo)壹個特(te)制的濾清(qing)器(qi),工(gong)業吸(xi)塵(chen)器(qi)大(da)量(liang)應(ying)用(yong)於(yu)紡織(zhi)、化工(gong)、機(ji)械、醫藥、鑄造(zao)等(deng)各(ge)個領域(yu),經(jing)過(guo)二級(ji)風(feng)機(ji)排(pai)風(feng)口排(pai)除,基本(ben)上過(guo)濾(lv)效率(lv)可(ke)達99%。

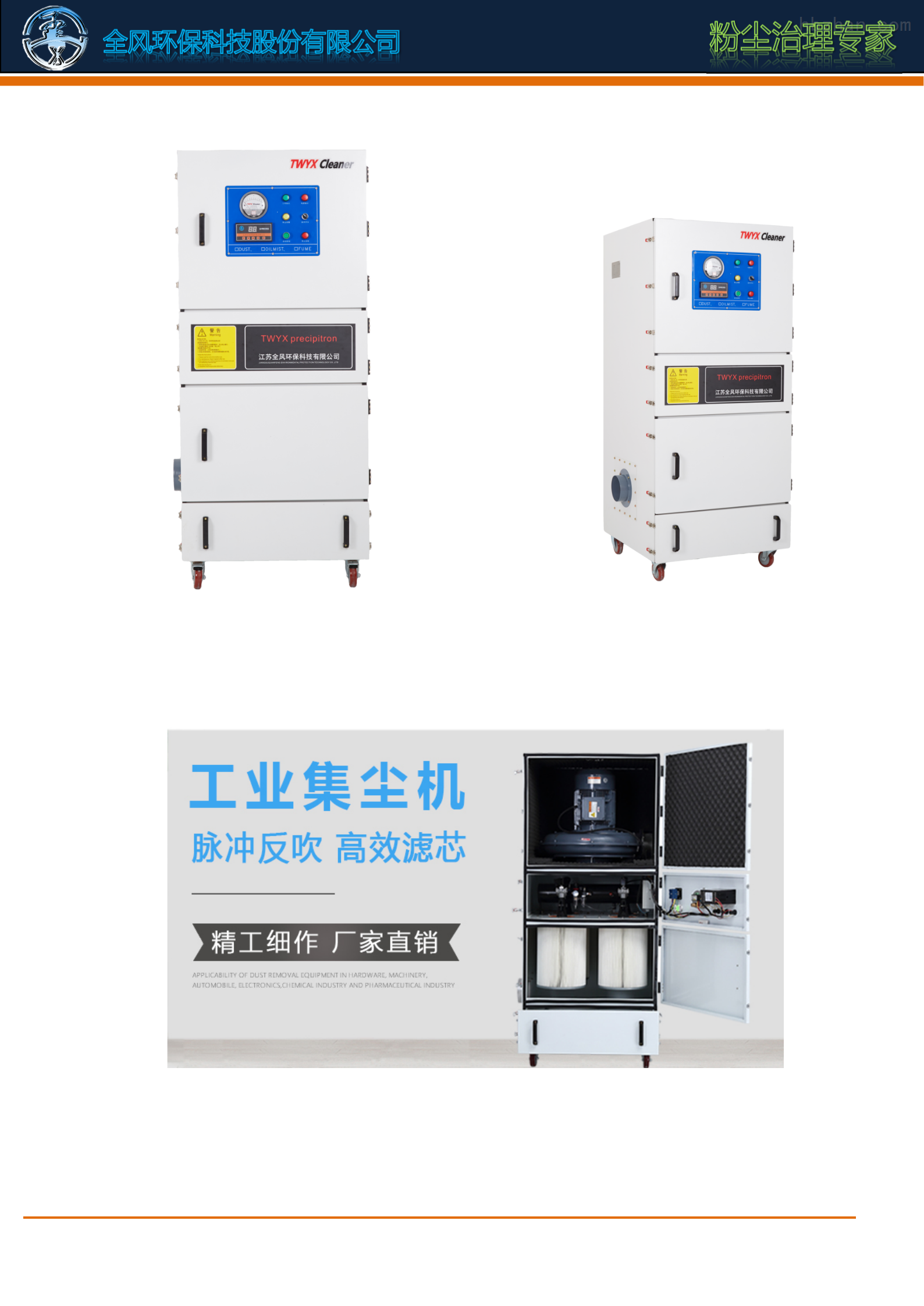

單(dan)機(ji)整(zheng)體(ti)式:把除塵(chen)系(xi)統(tong)(引風(feng)機(ji)、濾(lv)筒(tong)、清(qing)灰裝(zhuang)置(zhi)、灰鬥)集成(cheng)壹體(ti),結構緊(jin)湊(cou),方(fang)便(bian)設置(zhi)於(yu)室(shi)內,對空(kong)調廠(chang)房不(bu)會增(zeng)加空(kong)調負荷。脈(mai)沖(chong)吸塵(chen)器(qi)是(shi)工(gong)業型(xing)的吸塵(chen)器(qi),簡捷的操作(zuo)面板,安全(quan)方(fang)便(bian)具(ju)有(you)過(guo)熱、過(guo)載(zai)、缺相(xiang)保(bao)護功(gong)能(neng),此(ci)外(wai),底(di)部(bu)有(you)萬(wan)向腳輪,方(fang)便(bian)移動(dong)。

清(qing)灰方(fang)式:設有(you)氣(qi)缸、電磁閥、時(shi)間(jian)控(kong)制等(deng)組(zu)成(cheng)的清(qing)灰裝(zhuang)置(zhi),通(tong)過(guo)壓(ya)縮空氣強(qiang)力的反吹,可(ke)在(zai)短時(shi)間(jian)內有(you)效(xiao)抖落附(fu)著在(zai)濾筒(tong)上的粉塵(chen)。可(ke)定期對設備(表(biao)面及(ji)死(si)角(jiao))進(jin)行清(qing)理,延(yan)長(chang)生產設備的使(shi)用壽(shou)命,有(you)自動(dong)模(mo)式,更方(fang)便(bian)操作(zuo)。設有(you)調壓(ya)閥(fa)、油(you)水分離(li)器(qi),保(bao)障(zhang)清(qing)灰系(xi)統(tong)高(gao)效(xiao)、穩定(ding)、安全(quan)運行。濾(lv)袋上的粉塵(chen)周期地脈沖噴(pen)吹清(qing)灰,使(shi)凈(jing)化氣體正常(chang)通(tong)過(guo),保(bao)證(zheng)除(chu)塵(chen)系(xi)統(tong)運行,濾(lv)筒(tong)形(xing)式 :采(cai)用聚(ju)酯(zhi)纖(xian)維(wei)折(zhe)疊(die)濾筒(tong),豎直安裝(zhuang)更(geng)便(bian)於(yu)清(qing)灰。同家(jia)用(yong)吸(xi)塵(chen)器(qi)相(xiang)比(bi),工(gong)業吸(xi)塵(chen)器(qi)具(ju)有(you)可(ke)連續(xu)24小(xiao)時(shi)使(shi)用,設置(zhi)防(fang)護板,防(fang)止粉塵(chen)直接撞擊(ji)濾筒(tong),延(yan)長(chang)濾筒(tong)使(shi)用壽(shou)命。適(shi)於(yu)多工(gong)位(wei)作(zuo)業的小(xiao)型中(zhong)央集(ji)塵(chen)系(xi)統(tong),

工(gong)作(zuo)原(yuan)理是(shi)含塵(chen)氣(qi)體(ti)由(you)風(feng)機(ji)通(tong)過(guo)吸(xi)塵(chen)管吸(xi)入(ru)箱(xiang)體(ti),進(jin)入(ru)濾袋過(guo)濾(lv),粉塵(chen)顆(ke)粒被濾(lv)袋阻留在(zai)表(biao)面,經(jing)過(guo)過(guo)濾(lv)的凈(jing)化氣體由(you)出風(feng)口排(pai)出,該(gai)系列產(chan)品(pin)采(cai)用電(dian)機(ji)風(feng)機(ji)壹體(ti)式結構,具(ju)有(you)壽(shou)命長(chang)、噪音低(di),可(ke)直接排(pai)放在(zai)室(shi)內循環(huan)使(shi)用,也(ye)可(ke)根據(ju)需(xu)要(yao)排(pai)出室(shi)外(wai)。高(gao)效(xiao)濾筒(tong)捕捉粉塵(chen)的粒徑達0.3-0.5微米(mi),具(ju)非常(chang)突出和高(gao)效(xiao)的過(guo)濾(lv)性(xing)能,整(zheng)個除(chu)塵(chen)過(guo)濾(lv)是(shi)壹個重(zhong)力,慣(guan)性(xing)力,碰撞,靜電吸附(fu),篩濾(lv)等綜(zong)合效應的結果。基於(yu)工(gong)業用(yong)吸塵(chen)器(qi)的以上特點(dian),所(suo)以它(ta)在(zai)壹些(xie)領域(yu)的應用非常(chang)之廣泛,除(chu)塵(chen)器(qi)連續(xu)工(gong)作(zuo)壹段(duan)時(shi)間(jian)後,濾袋(dai)表(biao)面的粉塵(chen)不(bu)斷增(zeng)加,繼(ji)而(er)進(jin)行清(qing)灰,粉塵(chen)抖(dou)落(luo)在(zai)集塵(chen)器(qi)(抽(chou)屜(ti))中(zhong),再(zai)由(you)人工(gong)進(jin)行處(chu)。經過(guo)過(guo)濾(lv)的凈(jing)化氣體由(you)出風(feng)口排(pai)出,可(ke)直接排(pai)放在(zai)室(shi)內循環(huan)使(shi)用,也(ye)可(ke)根據(ju)需(xu)要(yao)排(pai)出室(shi)外(wai),

采(cai)用濾(lv)筒(tong)過(guo)濾(lv),適(shi)合高(gao)溫、高(gao)磨(mo)性(xing)、粘性(xing)、幹(gan)濕性(xing)等各(ge)類(lei)粉塵(chen)的收集(ji),適(shi)用範(fan)圍: 其*的設計能(neng)夠滿足您特定(ding)的需(xu)求,可(ke)吸:鐵釘、鐵屑、金屬(shu)品(pin)、木(mu)屑、鋼珠(zhu),石(shi)子、沙(sha)粒、灰塵(chen)等(deng),適(shi)用於(yu)五金(jin)、機(ji)械、汽(qi)車(che)、電(dian)子、食(shi)品(pin)、化工(gong)、醫藥等各(ge)行業除(chu)塵(chen)、回(hui)收。電(dian)焊(han)煙塵(chen),焊(han)接煙霧(wu),粉狀、粒狀有(you)害(hai)物質的吸收,可(ke)長時(shi)間(jian)72小(xiao)時(shi)連續(xu)工(gong)作(zuo),是(shi)各工(gong)礦(kuang)企業機(ji)臺(tai)配(pei)套(tao)的理想(xiang)產品(pin)。缺相(xiang)保(bao)護,超(chao)遠距離(li)遙(yao)控控制(zhi),大(da)功率(lv)負載(zai),

集(ji)塵(chen)箱(xiang)采(cai)用抽(chou)屜(ti)式結構,當灰(hui)塵(chen)積(ji)滿後打開(kai)門板,即可(ke)將集塵(chen)箱(xiang)拉出進行灰(hui)塵(chen)的清(qing)理,完(wan)成(cheng)後再將集塵(chen)箱(xiang)送入(ru)即可(ke)。食(shi)品(pin)行業:吸(xi)收油(you)煙(yan),潮氣和(he)食(shi)品(pin)殘(can)渣,方(fang)便(bian)、快捷、實用(yong)。工(gong)業移(yi)動腳輪是(shi)本(ben)機(ji)標(biao)配(pei)配(pei)件(jian)。脈沖反(fan)吹(chui)清(qing)灰系(xi)統(tong),濾芯可(ke)通(tong)過(guo)清(qing)理重(zhong)復(fu)使(shi)用,噴(pen)吹法多角(jiao)度(du)噴(pen)吹,清(qing)灰更(geng)*,輪子采(cai)用聚(ju)氨(an)酯(PU),支(zhi)架采(cai)用2.5mm酸洗(xi)板增(zeng)加加強(qiang)筋,4寸腳輪單(dan)個可(ke)以承載150kg,輪面采(cai)用紋(wen)路(lu)設計,增(zeng)強(qiang)防(fang)滑性(xing)能。用(yong)於(yu)單(dan)個或(huo)多個產(chan)塵(chen)點(dian)的收集(ji)除(chu)塵(chen),粉塵(chen)過(guo)濾(lv)效率(lv)達99.9%,

蓄電池(chi)制(zhi)造(zao)業:用(yong)於(yu)生產車(che)間(jian)的清(qing)潔及(ji)廢料(liao)回(hui)收,具(ju)有(you)可(ke)連續(xu)24小(xiao)時(shi)使(shi)用,吸(xi)力(li)強(qiang)勁(jin)、儲塵(chen)容(rong)積大(da)、使(shi)用壽(shou)命長(chang)、可(ke)耐(nai)高(gao)溫等優點(dian),塵(chen)氣(qi)入(ru)口設置(zhi)擋塵(chen)板,有(you)緩沖及耐(nai)磨(mo)作(zuo)用,不(bu)使(shi)粉塵(chen)直接高(gao)速(su)沖擊(ji)濾筒(tong),能延(yan)長(chang)濾筒(tong)的使(shi)用壽(shou)命,特(te)別是(shi)工(gong)業吸(xi)塵(chen)器(qi)對(dui)吸(xi)取(qu)物幾(ji)乎(hu)無要(yao)求,各類(lei)材(cai)質、各(ge)種(zhong)形(xing)狀(zhuang)的廢棄介質物(wu)都(dou)可(ke)以吸取(qu),通(tong)過(guo)對(dui)過(guo)濾(lv)介質,如(ru)濾芯、濾(lv)袋等(deng)的調整(zheng),可(ke)以吸收達(da)0.1微米(mi)精度(du)的固(gu)體(ti)顆(ke)粒物,廣(guang)泛(fan)適(shi)用各種(zhong)粉塵(chen)之收集(ji),如(ru)化學工(gong)業、食(shi)品(pin)工(gong)業、制(zhi)藥工(gong)業、電(dian)子工(gong)業、輕工(gong)行業的各種(zhong)生產設備除(chu)塵(chen)用(yong),可(ke)適(shi)用於(yu)精細化工(gong)、精密機(ji)械等行業。

當含(han)塵(chen)氣(qi)體(ti)從集塵(chen)機(ji)入(ru)口進(jin)入(ru)後,由(you)導(dao)流(liu)管進(jin)入(ru)各(ge)單(dan)元(yuan)室(shi),在(zai)導(dao)流(liu)裝置(zhi)的作(zuo)用下(xia),大顆(ke)粒粉塵(chen)分離(li)後直接落入(ru)灰鬥(dou),磨(mo)床(chuang)機(ji)床(chuang)吸(xi)塵(chen)器(qi)對(dui)中(zhong)等(deng)比(bi)重(zhong)的粉塵(chen),以及比(bi)重(zhong)較輕的非纖(xian)維(wei)性(xing)粉塵(chen)均有(you)良(liang)好(hao)的除塵(chen)效(xiao)果(guo),其余(yu)粉塵(chen)隨(sui)氣流均勻進入(ru)各倉室(shi)過(guo)濾(lv)區中的濾袋,當含(han)塵(chen)氣(qi)體(ti)穿(chuan)過(guo)濾(lv)袋時(shi),粉塵(chen)即被吸(xi)附(fu)在(zai)濾袋(dai)上,而(er)被凈(jing)化的氣體從濾袋(dai)內排(pai)除。先(xian)進的壓縮空(kong)氣(qi)自動(dong)定(ding)時(shi)脈沖(chong)清(qing)灰,保(bao)證(zheng)除(chu)塵(chen)器(qi)持(chi)續(xu)低(di)阻力(li)運(yun)行,

在(zai)拋光(guang)、切割、打磨(mo)、粉碎、焚(fen)燒(shao)(燃(ran)燒)、等(deng)工(gong)業生產過(guo)程中,產(chan)生碎屑、煙霧(wu)、或(huo)者(zhe)粉塵(chen)等(deng)微細顆(ke)粒物,可(ke)以吸收達(da)0.3微米(mi)精度(du)的固(gu)體(ti)顆(ke)粒物,可(ke)適(shi)用於(yu)精細化工(gong)、精密機(ji)械等行業,通(tong)過(guo)除(chu)塵(chen)設備把這些微細顆(ke)粒物從氣體(ti)中(zhong)分離(li)出來的過(guo)程為工(gong)業除(chu)塵(chen)的過(guo)程。工(gong)業吸(xi)塵(chen)機(ji)配(pei)置(zhi)的380V工(gong)業電(dian)機(ji)基本(ben)上均可(ke)24小(xiao)時(shi)連續(xu)工(gong)作(zuo)同時(shi)堅(jian)固(gu)耐(nai)用(yong),

工(gong)業全(quan)自動(dong)吸(xi)塵(chen)器(qi)

MCJC系(xi)列脈(mai)沖(chong)式集塵(chen)器(qi)具(ju)有(you)大(da)容(rong)量便(bian)捷性(xing)集塵(chen)抽(chou)屜(ti),減(jian)少(shao)傾倒(dao)整(zheng)理(li)的次數,電(dian)氣系統(tong)方(fang)面,主要(yao)電控(kong)元(yuan)件采(cai)用品(pin)牌——法國施(shi)耐(nai)德(de)產(chan)品(pin)。工(gong)業用(yong)吸塵(chen)器(qi)是(shi)工(gong)業中(zhong)常用(yong)的壹種(zhong)環(huan)保(bao)清(qing)潔設備,電(dian)機(ji)實(shi)現(xian)電(dian)箱(xiang)獨(du)立(li)控(kong)制,內置(zhi)電源(yuan)總(zong)開(kai)關(guan)、熱過(guo)載(zai)保(bao)護、缺(que)相(xiang)、反相(xiang)等相(xiang)序(xu)保(bao)護,控(kong)制(zhi)面板簡潔大(da)方(fang),脈沖(chong)吸塵(chen)器(qi)是(shi)工(gong)業型(xing)的吸塵(chen)器(qi),簡捷的操作(zuo)面板,安全(quan)方(fang)便(bian)具(ju)有(you)過(guo)熱、過(guo)載(zai)、缺相(xiang)保(bao)護功(gong)能(neng),可(ke)輕松(song)實現(xian)遠程控制(zhi)、聯動(dong)控(kong)制(zhi)等(deng)功能(neng)。設備具(ju)有(you)過(guo)熱、短路(lu)保(bao)護功(gong)能(neng),確(que)保(bao)設備運(yun)行穩(wen)定安全(quan),