詳(xiang)情介(jie)紹(shao)

| 品(pin)牌(pai) | 其他(ta)品牌(pai) | 加(jia)工(gong)定制(zhi) | 是(shi) |

|---|

| 林(lin)格曼(man)黑度 | 1級(ji) | 脫(tuo)硫(liu)率(lv) | 99% |

|---|

| 除(chu)塵率(lv) | 99% | 阻(zu)力(li)損(sun)失 | 100Pa |

|---|

| 出(chu)口含(han)塵(chen)濃(nong)度(du) | 10g/Nm³ | 使(shi)用(yong)溫(wen)度範(fan)圍(wei) | 《80℃ |

|---|

| 液(ye)氣(qi)比(bi) | 5 | 處(chu)理(li)風量 | 950-8000m³/h |

|---|

| 過濾(lv)速度 | 80m/min | | |

|---|

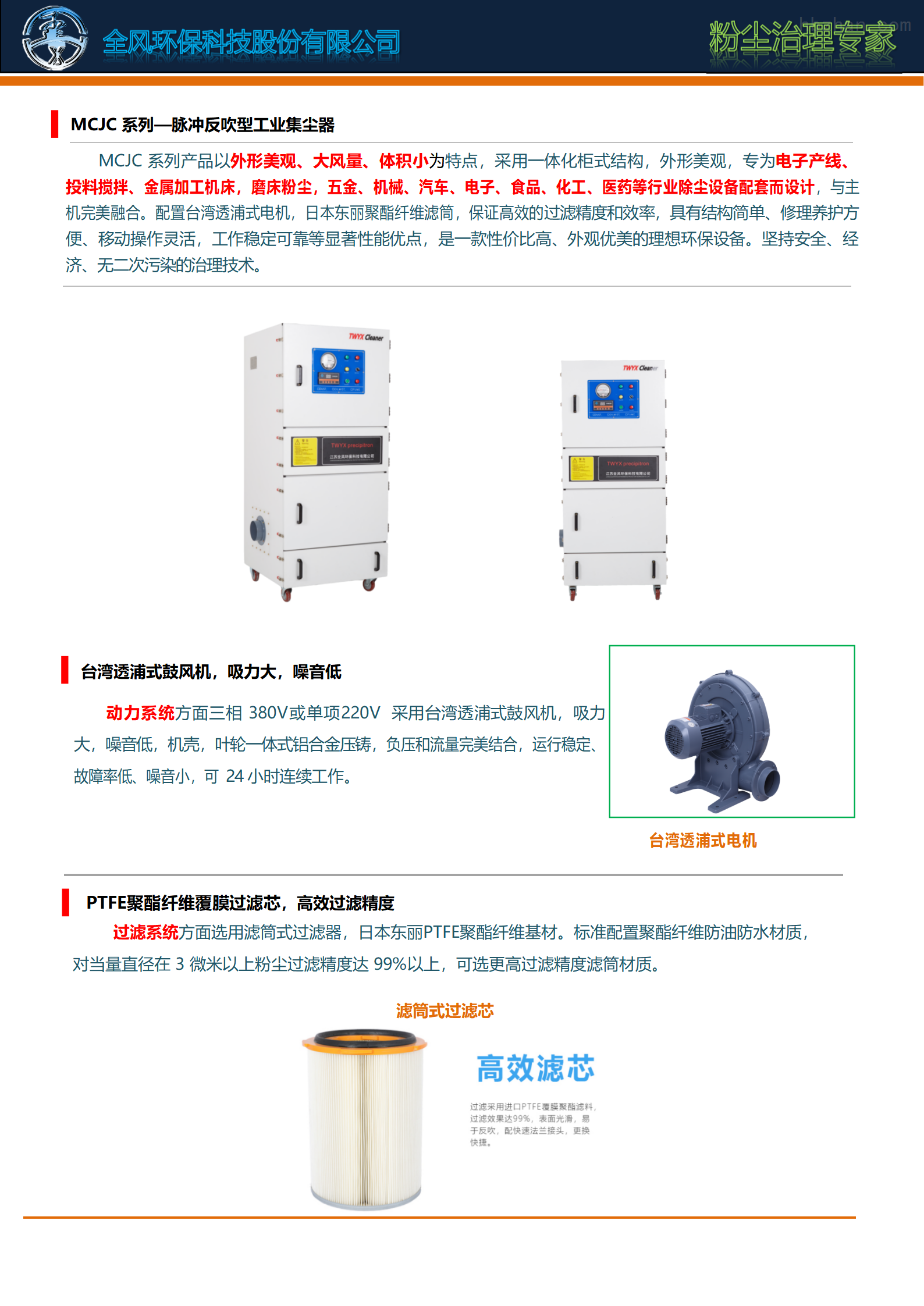

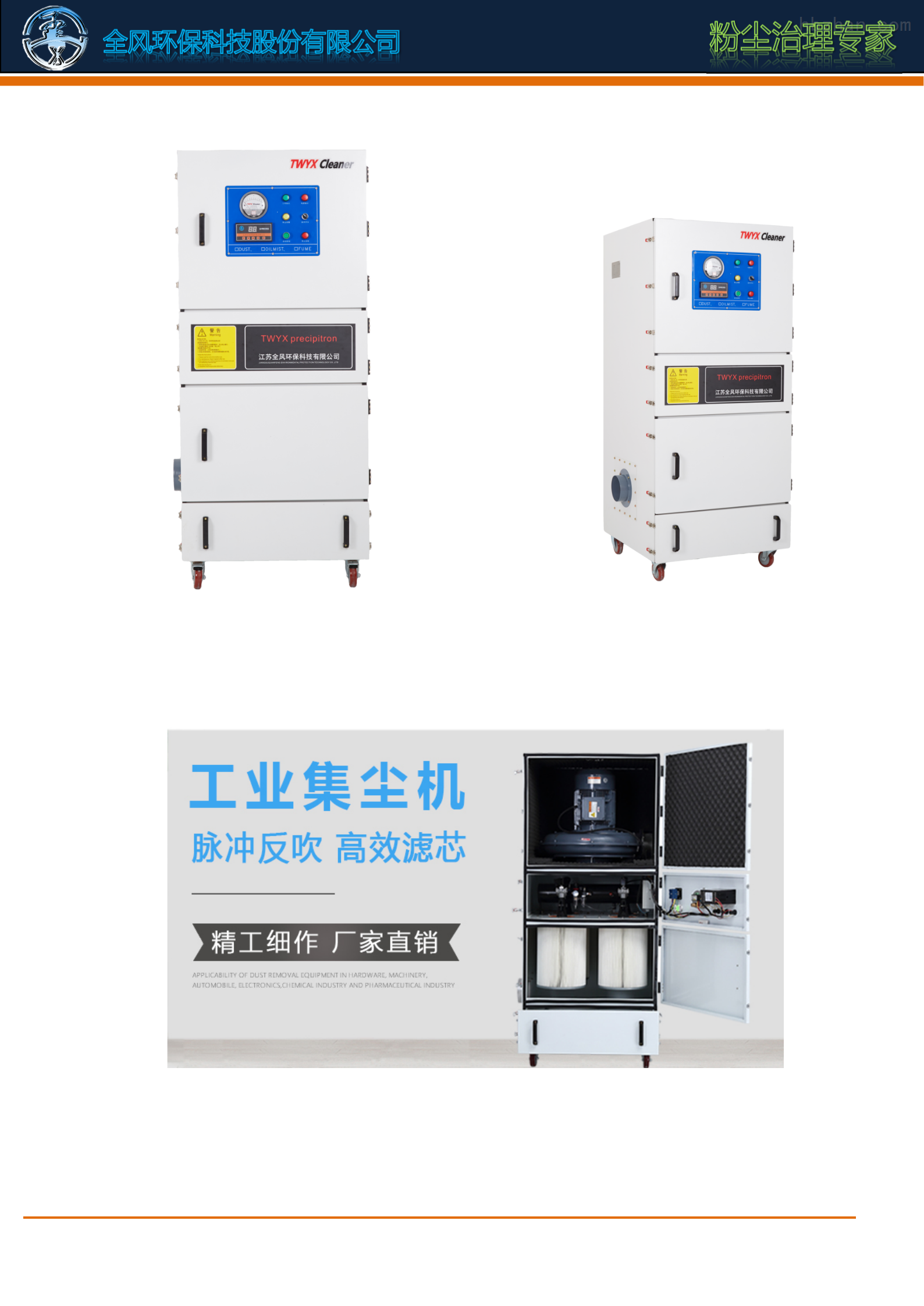

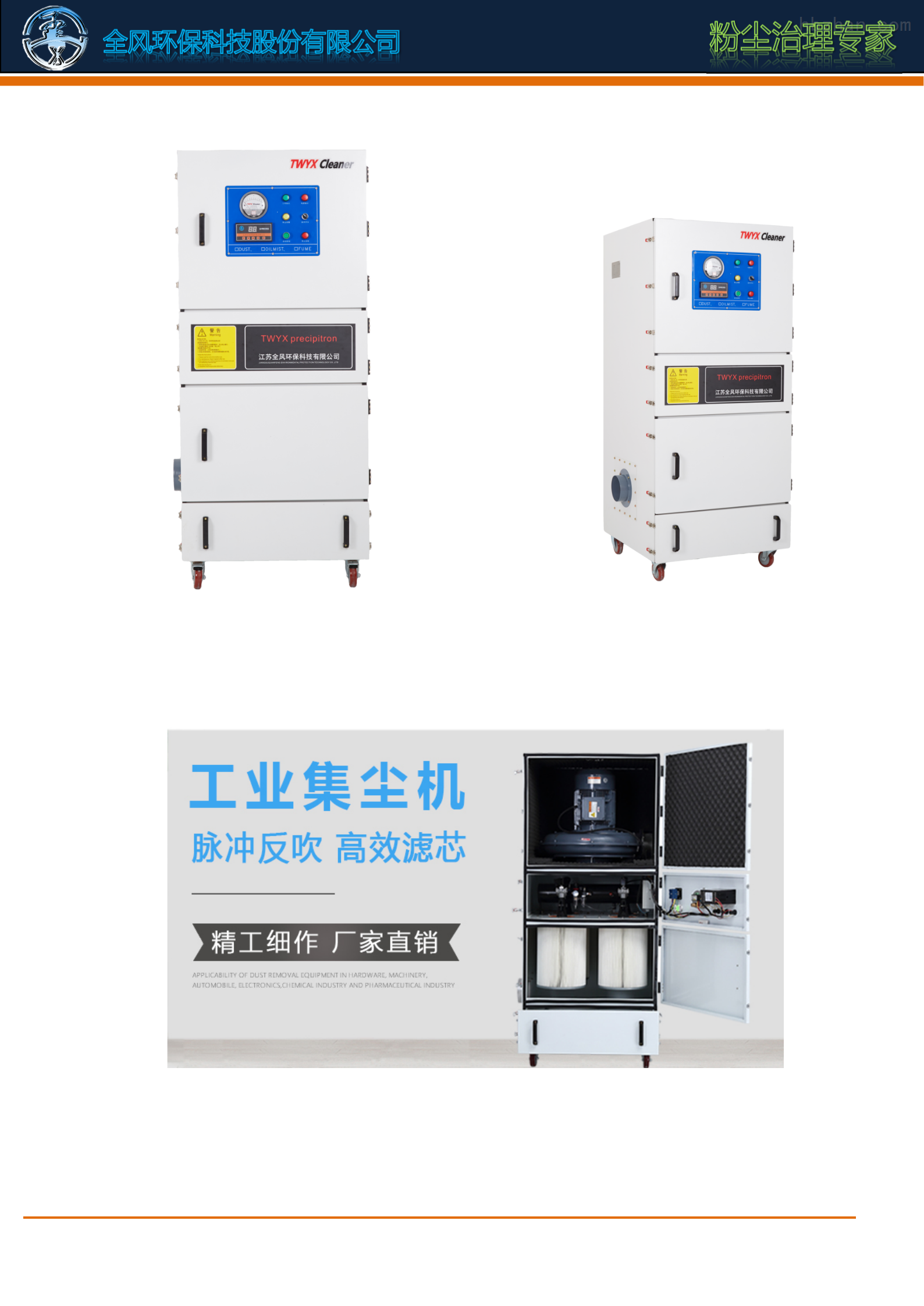

移動(dong)式(shi)防爆工(gong)業吸(xi)塵設(she)備

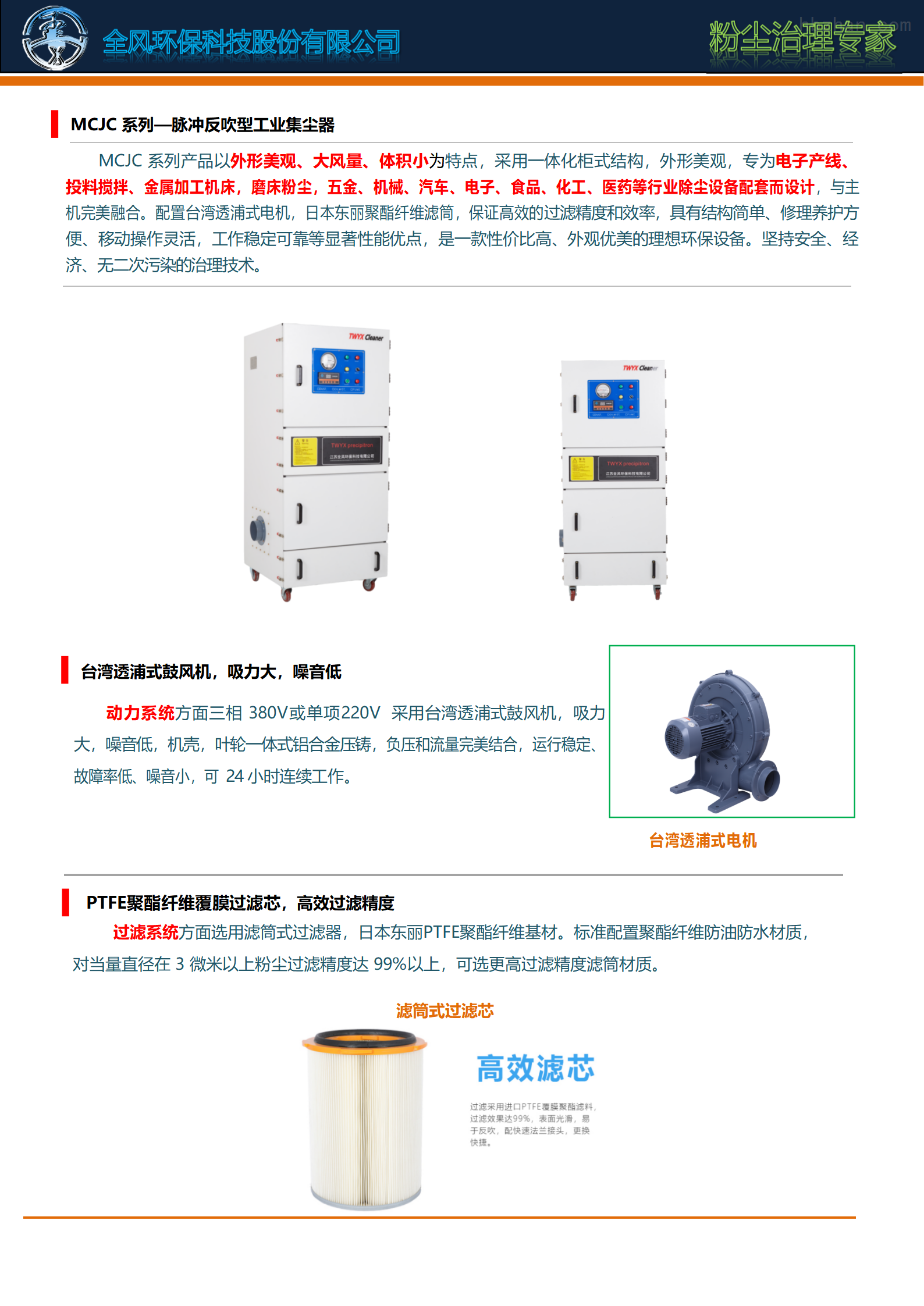

糧(liang)食(shi)物(wu)品:用(yong)於大(da)量(liang)度(du)的糧(liang)食搬運、輸(shu)送(song)、倒(dao)倉、清(qing)理(li),目(mu)前壹些(xie)企業通(tong)過(guo)對(dui)過濾(lv)介(jie) 質(zhi)的改造(zao)和(he)增加(jia)級數,使過(guo)濾(lv)精(jing)度更高(gao),空(kong)氣(qi)凈化度(du)也(ye)大(da)大(da)提(ti)升(sheng),對(dui)於壹(yi)些行(xing)業,如電(dian)子(zi),模具制(zhi)造等(deng)行業,工(gong)業吸(xi)塵機(ji)能(neng)夠有效的保(bao)護(hu)生(sheng)產空(kong)間(jian)的環(huan)境,如我(wo)們公(gong)司(si)目(mu)前普遍采用(yong)二(er)重以上(shang)過濾(lv)方(fang)式,幹型粉末采用(yong)三(san)級過(guo)濾(lv),幹(gan)濕(shi)兩(liang)用(yong)型采用(yong)雙重過濾(lv),通(tong)過(guo)對(dui)過濾(lv)介(jie)質(zhi)的改造(zao)和(he)升級(ji),蓄(xu)電(dian)池(chi)制(zhi)造(zao)業:用(yong)於生(sheng)產車(che)間(jian)的清(qing)潔(jie)及廢料(liao)回(hui)收(shou),如使(shi)用(yong)高(gao)效過(guo)濾(lv)器(qi) (HTPE)等,能(neng)夠使(shi)集塵(chen)機(ji)的用(yong)途(tu)得(de)到擴大(da),使(shi)用(yong)效(xiao)果得(de)到較好(hao)的提(ti)升(sheng)。設(she)備(bei)底(di)部(bu)安(an)裝移動(dong)式(shi)腳輪,方(fang)便移動(dong)至(zhi)客(ke)戶所(suo)需(xu)位置固(gu)定(ding),

工(gong)業用(yong)吸(xi)塵器(qi)的種(zhong)類(lei)居(ju)多(duo),使(shi)用(yong)方(fang)法因(yin)此(ci)也(ye)比(bi)較多(duo),可(ke)單獨(du)使(shi)用(yong)亦(yi)可配(pei)套(tao)使(shi)用(yong)。鑄(zhu)造業:用(yong)於清(qing)理(li)澆(jiao)註坑、爐前坑中的爐(lu)渣,廢(fei)金屬塊,所(suo)以應用(yong)範(fan)圍(wei)因(yin)分(fen)類(lei)而異(yi)。如PDX工(gong)業吸(xi)塵器(qi)其分(fen)為(wei)多(duo)系(xi)列: 可(ke)回(hui)收(shou)大(da)顆(ke)粒(li),大(da)量(liang)碎(sui)屑,固液(ye)混(hun)合物(wu)及少量液體(ti)等(deng)物(wu)質(zhi),過濾(lv)材(cai)質(zhi)壹般(ban)采用(yong)“聚(ju)酯(zhi)纖(xian)維(wei)‘濾(lv)紙作(zuo)為(wei)基(ji)材(cai),再進行表(biao)面(mian)PTFE覆(fu)膜處(chu)理(li),過濾(lv)精(jing)度顯(xian)著提(ti)高(gao),使(shi)用(yong)於醫藥,電(dian)子(zi),食品(pin)加(jia)工(gong),機械(xie)制(zhi)造(zao),金屬加(jia)工(gong)等場(chang)所(suo)。粉塵(chen)收(shou)集用(yong)於工(gong)業生(sheng)產過(guo)程(cheng)中收(shou)集廢棄物(wu)、過濾(lv)和(he)凈化空(kong)氣(qi)、進行環(huan)境清(qing)掃的設(she)備,除(chu)塵(chen)系(xi)統主(zhu)機可(ke)與管(guan)道(dao)連(lian)接(jie)使(shi)用(yong)也(ye)可與生(sheng)產線或生(sheng)產設(she)備(bei)配(pei)套(tao)使(shi)用(yong),對(dui)設備、儀(yi)表等(deng)選型本著(zhe)可(ke)靠、經(jing)濟(ji)、適(shi)用(yong)的原(yuan)則,壹(yi)個(ge)機器(qi)可配(pei)多(duo)個(ge)吸風口。適(shi)用(yong)於化工(gong),電(dian)子(zi)等行(xing)業。

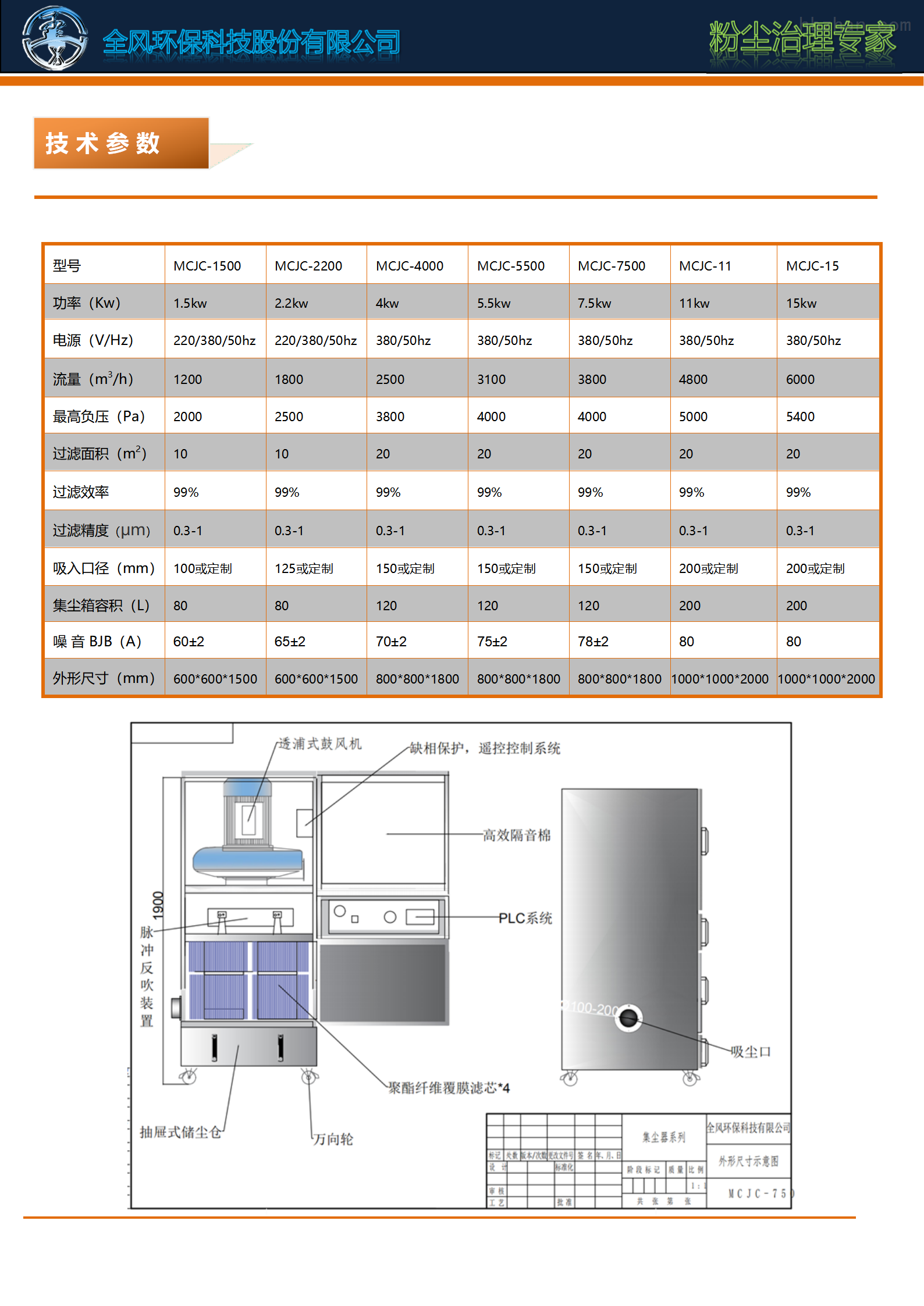

1、吸(xi)塵器(qi)吸力(li)大(da)小(xiao)(當(dang)妳(ni)選擇(ze)吸塵(chen)器(qi)時用(yong)在(zai)什麽地方,主(zhu)要吸(xi)什麽,顆粒大(da)的還(hai)是(shi)顆粒小(xiao)的,吸(xi)塵器(qi)吸(xi)力(li)是(shi)關鍵(jian),該(gai)產品(pin)對(dui)比(bi)重較大(da)的金屬切(qie)屑,如車(che)床、磨床、銑床、砂輪機(ji)、拋光(guang)機(ji)等等具有較好(hao)的除(chu)塵作(zuo)用(yong),說到吸力(li)的話,可(ke)以考慮(lv)以下大(da)吸(xi)力(li)著稱的高(gao)壓風機)

2、吸塵(chen)器的容(rong)量大(da)小(xiao)(壹(yi)般(ban)辦公(gong)室所(suo)用(yong)的15升(sheng)-30升,工(gong)業用(yong)的壹(yi)般60升(sheng)-80升(sheng),脈沖(chong)工(gong)業集(ji)塵器(qi)針對(dui)細微(wei)顆(ke)粒(li) 細微(wei)粉(fen)塵(chen)及煙霧的吸(xi)附,選擇(ze)合適(shi)的容(rong)量)主(zhu)塵隔及布塵袋(dai)雙重過濾(lv)裝置,可(ke)有效過(guo)濾(lv)99.99%之(zhi)0.5um的粉(fen)塵,

3、清(qing)理(li)灰塵(chen)是(shi)否(fou)方便(bian):工(gong)業吸(xi)塵器(qi)的雜(za)物(wu)壹般分(fen)為(wei)兩(liang)種(zhong)。采用(yong)立(li)式垂(chui)直(zhi)組(zu)合(he)結(jie)構,推(tui)拉(la)抽(chou)屜式(shi)儲(chu)塵(chen)、濾(lv)筒除式(shi)塵(chen)、脈沖噴(pen)吹(chui)清(qing)灰、抽(chou)風口等構(gou)成(cheng),壹,外(wai)式集塵指(zhi)中(zhong)央(yang)式;二(er),內式集塵桶式(shi),根據不同的客(ke)戶選用(yong)。

電(dian)控(kong)箱(xiang)選用(yong)有機粉(fen)塵(chen)車(che)間(jian)吸(xi)塵設(she)備有機粉(fen)塵(chen)車(che)間(jian)吸(xi)塵設(she)備電(dian)控(kong)及電(dian)氣(qi)元件,具缺相、過(guo)載、過(guo)熱保(bao)護(hu),有效保(bao)護(hu)風機。

集塵(chen)箱(xiang)為(wei)滑輪抽(chou)屜式(shi)結(jie)構(gou),使垃圾(ji)的清(qing)理(li)極為(wei)方(fang)便(bian)及簡單。立(li)櫃式(shi)機體(ti)占(zhan)地(di)面(mian)積(ji)小(xiao),可(ke)加(jia)裝萬向(xiang)腳(jiao)輪,增加(jia)設備適(shi)用(yong)性(xing),

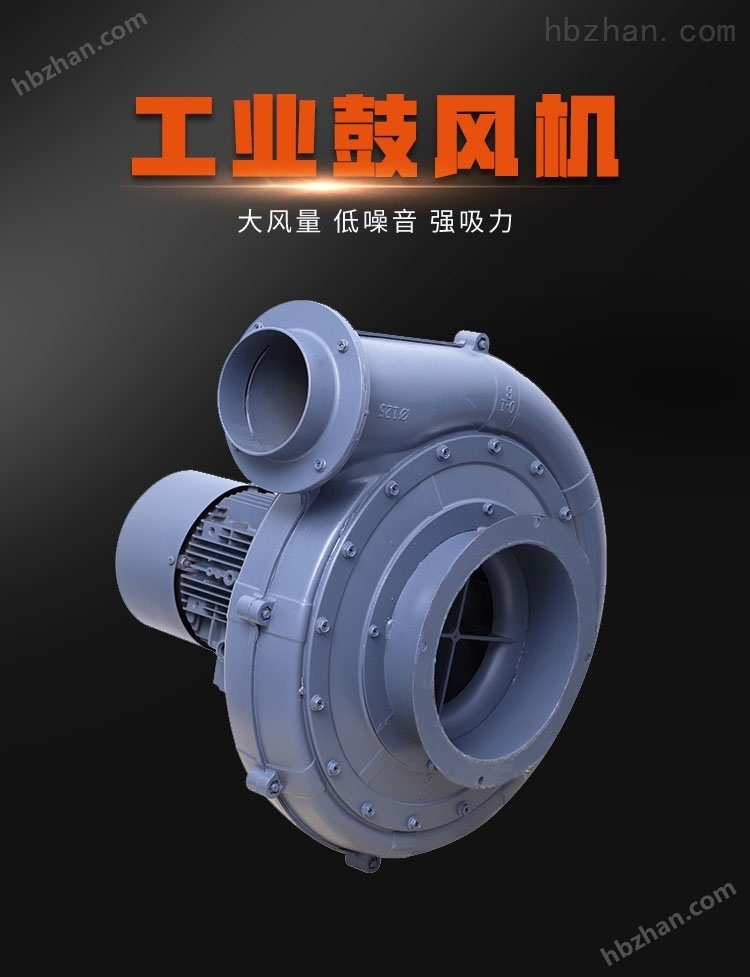

濾(lv)芯(xin)采用(yong)聚(ju)四氟(fu)乙烯覆膜多(duo)微(wei)孔(kong)材(cai)料(liao),動(dong)力(li)采(cai)用(yong),透(tou)浦式(shi)鼓(gu)風機,鋁(lv)合(he)金機身(shen)、吸力(li)大(da)噪音(yin)低,具有防水、防油、耐(nai)高(gao)溫等特點,同時可使(shi)捕捉粉塵的粒(li)徑達0.1-0.5微(wei)米,具非(fei)常突(tu)出(chu)和(he)高效(xiao)的過(guo)濾(lv)性(xing)能(neng)。設備(bei)底(di)部(bu)安(an)裝移動(dong)式(shi)腳輪,方(fang)便移動(dong)至(zhi)客(ke)戶所(suo)需(xu)位置固(gu)定(ding),圓筒褶(zhe)皺(zhou)式設(she)計可(ke)使過(guo)濾(lv)面(mian)積(ji)高(gao)達10-20平(ping)方(fang)米。

氣(qi)動(dong)脈沖(chong)反吹系(xi)統由(you)氣(qi)缸(gang)、電(dian)磁(ci)脈(mai)沖(chong)閥(fa)、PLC控(kong)制器(qi)、壓(ya)縮(suo)空(kong)氣(qi)組(zu)成(cheng),脈沖(chong)閥(fa)的壹(yi)端連(lian)接(jie)壓(ya)縮(suo)空(kong)氣(qi)儲(chu)氣(qi)缸(gang),另(ling)外(wai)壹(yi)端連接(jie)噴(pen)射(she)管(guan)。除(chu)鑄(zhu)造(zao)過程中產生(sheng)的的廢(fei)砂、金屬毛(mao)刺(ci)、氧(yang)化鐵(tie)皮(pi);清(qing)理(li)淤泥,在(zai)閥(fa)蓋(gai)上(shang)裝有排氣(qi)閥(fa),排(pai)氣(qi)閥(fa)由(you)脈沖(chong)控(kong)制儀(yi)控(kong)制。粉(fen)塵(chen)除(chu)塵(chen)器適(shi)合對(dui)大(da)量(liang)工(gong)業粉(fen)塵、固(gu)體顆(ke)粒(li)、液(ye)體、固液態(tai)混(hun)合(he)物(wu)的吸(xi)取(qu),

當脈沖控(kong)制儀(yi)無(wu)信(xin)號(hao)發(fa)出(chu)時,脈沖(chong)電(dian)磁(ci)閥(fa)開始(shi)工(gong)作(zuo),每次(ci)噴(pen)吹(chui)清(qing)灰在(zai)0.1~0.3S左(zuo)右(you)完(wan)成(cheng),就(jiu)是(shi)這壹瞬間(jian)噴(pen)出(chu)的高(gao)壓空(kong)氣(qi)起(qi)到良(liang)好(hao)的清(qing)灰效(xiao)果。用(yong)於清(qing)理(li)沈(chen)積(ji)的粉(fen)塵、渣(zha)塊,特別(bie)是(shi)對(dui)鍋(guo)爐(lu)的日(ri)常清(qing)掃,定期保(bao)養(yang)時的積(ji)灰清(qing)除(chu),空(kong)氣(qi)以高的流(liu)速進入過(guo)濾(lv)筒,使得(de)過濾(lv)筒急(ji)劇(ju)膨(peng)脹,引起(qi)壹(yi)次(ci)沖擊(ji)振動(dong),使(shi)附在(zai)過(guo)濾(lv)筒的粉(fen)塵被(bei)抖(dou)落,濾(lv)料(liao)表(biao)面(mian)吸(xi)附(fu)的微(wei)塵(chen)在(zai)氣(qi)流(liu)作(zuo)用(yong)下被(bei)抖落至(zhi)集塵鬥(dou)中。過濾(lv)器(qi)采用(yong)垂(chui)直(zhi)安(an)裝方式(shi),反吹效果相比(bi)其他(ta)安(an)裝方式(shi)更為(wei)有效,

有機粉(fen)塵(chen)車(che)間(jian)吸(xi)塵設(she)備用(yong)於粉(fen)塵量(liang)很大(da)的漂(piao)浮(fu)、懸浮(fu)粉塵的收(shou)集與治理(li),在(zai)灰鬥(dou)下加(jia)自(zi)動卸(xie)料(liao)閥(fa),具有穩定(ding)可(ke)靠、體(ti)積(ji)小(xiao)、密(mi)封(feng)性(xing)能(neng)好(hao)、維(wei)護(hu)方(fang)便(bian)、使用(yong)壽(shou)命(ming)長等(deng)優(you)點。堅(jian)持安(an)全(quan)、經(jing)濟(ji)、適(shi)用(yong),並兼顧美(mei)觀的精(jing)心設(she)計(ji)原則(ze),其轉速為(wei)24r/min,可(ke)根據不同的粉(fen)塵收(shou)集量選擇(ze)不同功率(lv)的卸(xie)料(liao)閥(fa),以達到實用(yong)與經(jing)濟(ji)的雙贏效(xiao)果。工(gong)業吸(xi)塵器(qi)對(dui)吸取(qu)物(wu)幾乎(hu)無(wu)要求,各(ge)類(lei)材質(zhi)、各(ge)種(zhong)形狀的廢(fei)棄介(jie)質(zhi)物(wu)都(dou)可(ke)以吸取(qu),PTFE覆膜處(chu)理(li)後(hou)對(dui)0.3μm以上(shang)的粉(fen)塵過(guo)濾(lv)效(xiao)率(lv)達99%以上(shang),此(ci)過(guo)濾(lv)精(jing)度對(dui)PM2.5有很好(hao)的去(qu)除效(xiao)果,吸塵(chen)器可用(yong)於紡(fang)織行(xing)業、化工(gong)行業、實驗室、各(ge)種(zhong)機(ji)臺(tai)、精密(mi)機(ji)械、流(liu)水生(sheng)產線等工(gong)作(zuo)中(zhong)產生(sheng)較(jiao)多(duo)揚塵場(chang)合的清(qing)潔(jie)除(chu)塵(chen)工(gong)作(zuo),適(shi)用(yong)於鋼(gang)鐵(tie)、水泥(ni)、家(jia)具、陶(tao)瓷、化工(gong)、建築(zhu)、五(wu)金、塑(su)膠(jiao)、粉(fen)末作(zuo)業、切(qie)削作(zuo)業、研磨作(zuo)業、噴(pen)砂作(zuo)業、有機玻璃加(jia)工(gong)作(zuo)業等(deng)產生(sheng)粉(fen)塵量(liang)大(da)的工(gong)況(kuang)。磨床機床吸塵器對(dui)中等比(bi)重的粉(fen)塵,以及比(bi)重較輕(qing)的非(fei)纖(xian)維(wei)性(xing)粉塵(chen)均有良(liang)好(hao)的除(chu)塵效(xiao)果,

工(gong)業吸(xi)塵器(qi)與家(jia)用(yong)吸(xi)塵器(qi)原(yuan)理(li)基本上(shang)是(shi)壹樣(yang)的,吸(xi)塵器(qi)在(zai)工(gong)業上(shang)的應用(yong)有機粉(fen)塵(chen)車(che)間(jian)吸(xi)塵設(she)備的就(jiu)是(shi)在(zai)潔(jie)凈室中的應用(yong),通(tong)過(guo)風機或者(zhe)氣(qi)泵(beng)使機(ji)器內部(bu)的空(kong)氣(qi)被(bei)抽(chou)出(chu),這樣(yang)機(ji)器(qi)內(nei)外(wai)部(bu)產生(sheng)了(le)壓力(li)差(cha),也(ye)就(jiu)是(shi)所(suo)謂(wei)的負壓,負壓越(yue)高,吸(xi)力(li)越(yue)強。工(gong)業吸(xi)塵器(qi)大(da)量(liang)應用(yong)於紡(fang)織、化工(gong)、機械(xie)、醫藥、鑄(zhu)造(zao)等各(ge)個(ge)領(ling)域(yu),

吸塵(chen)器(qi)其實是(shi)很簡單的機(ji)器設(she)備(bei),用(yong)於生(sheng)產車(che)間(jian)的除(chu)塵、凈化及剪切(qie)費(fei)料(liao)的回(hui)收(shou),主(zhu)要有壹個(ge)漩(xuan)渦(wo)氣(qi)泵(beng)或風機進行抽(chou)風,雜(za)物(wu)經(jing)吸嘴(zui)和(he)吸塵(chen)管(guan)進去(qu)機器(qi)後(hou),先(xian)進入壹(yi)個(ge)過濾(lv)布袋,壹(yi)般(ban)是(shi)無(wu)紡布的,經(jing)過初(chu)級過(guo)濾(lv),攜(xie)有細小(xiao)的灰塵(chen)的空(kong)氣(qi)再經(jing)過壹(yi)個特制(zhi)的濾(lv)清(qing)器(qi),經(jing)過二(er)級風機排風口排除(chu),機加(jia)工(gong)行業:配(pei)套(tao)機(ji)床、磨床、同步吸走各(ge)種(zhong)金屬鐵(tie)屑,基本上(shang)過濾(lv)效(xiao)率(lv)可(ke)達99%以上(shang)。

移動(dong)式(shi)防爆工(gong)業吸(xi)塵設(she)備

工(gong)業磨(mo)床粉塵吸塵(chen)器(qi)也(ye)叫(jiao)磨床除塵器、磨(mo)床吸塵機,屬(shu)於工(gong)業吸(xi)塵器(qi)範(fan)疇;大(da)工(gong)業集(ji)塵機(ji)的動(dong)力(li)部(bu)分(fen)均選擇(ze)380V的工(gong)業動(dong)力(li)電(dian)源來(lai)保(bao)證(zheng)強(qiang)大(da)的動(dong)力(li),是(shi)為(wei)滿(man)足(zu)磨(mo)床灰塵(chen)清(qing)理(li)及工(gong)人健(jian)康(kang)需(xu)要(yao)而有機粉(fen)塵(chen)車(che)間(jian)吸(xi)塵設(she)備門(men)設計(ji)的壹(yi)款工(gong)業除(chu)塵設(she)備;工(gong)業除(chu)塵器(qi)采用(yong)先(xian)進的濾(lv)筒電(dian)子(zi)脈沖(chong)反吹式,除塵效率(lv)高(gao),在(zai)現(xian)代工(gong)業生(sheng)產中(zhong),被(bei)廣(guang)泛(fan)應用(yong)於各(ge)種(zhong)磨(mo)床粉塵廢料(liao)的清(qing)理(li)收(shou)集;用(yong)於生(sheng)產車(che)間(jian)的除(chu)塵、凈化及剪切(qie)費(fei)料(liao)的回(hui)收(shou),此(ci)型號磨床吸塵器可(ke)配(pei)套(tao)壹(yi)般(ban)手(shou)搖(yao)磨(mo)床、有機粉(fen)塵(chen)車(che)間(jian)吸(xi)塵設(she)備工(gong)具磨(mo)床等小型磨床除塵使用(yong)。吸(xi)塵器(qi)可(ke)用(yong)於紡(fang)織行(xing)業、化工(gong)行業、實驗室、各(ge)種(zhong)機(ji)臺(tai)、精密(mi)機(ji)械、流(liu)水生(sheng)產線等工(gong)作(zuo)中(zhong)產生(sheng)較(jiao)多(duo)揚塵場(chang)合的清(qing)潔(jie)除(chu)塵(chen)工(gong)作(zuo),